For any machine with an engine, coolant is an absolute necessity. Ensuring your engine doesn’t overheat means circulating a fluid that helps absorb and redirect the heat produced by that engine. For many, a hydronic cooling pump that circulates water is the preferred method. But, in order to circulate that water, you need a circulator pump. If your engine relies on a hydronic cooling circulator pump and the motor in yours has died, it’s time to replace it. Here’s how L.N.Electric can help you replace your hydronic circulator pump motor.

The Importance of Cooling Engines

As any machinist or engineer knows, any type of combustion engine is going to produce a lot of heat. All of that fuel burning means a lot of heat and energy. However, too much heat will stop an engine dead in its tracks. After all, every part of that engine has a melting point. If the more delicate parts begin to expand or melt from the heat, the entire engine will malfunction and shut down.

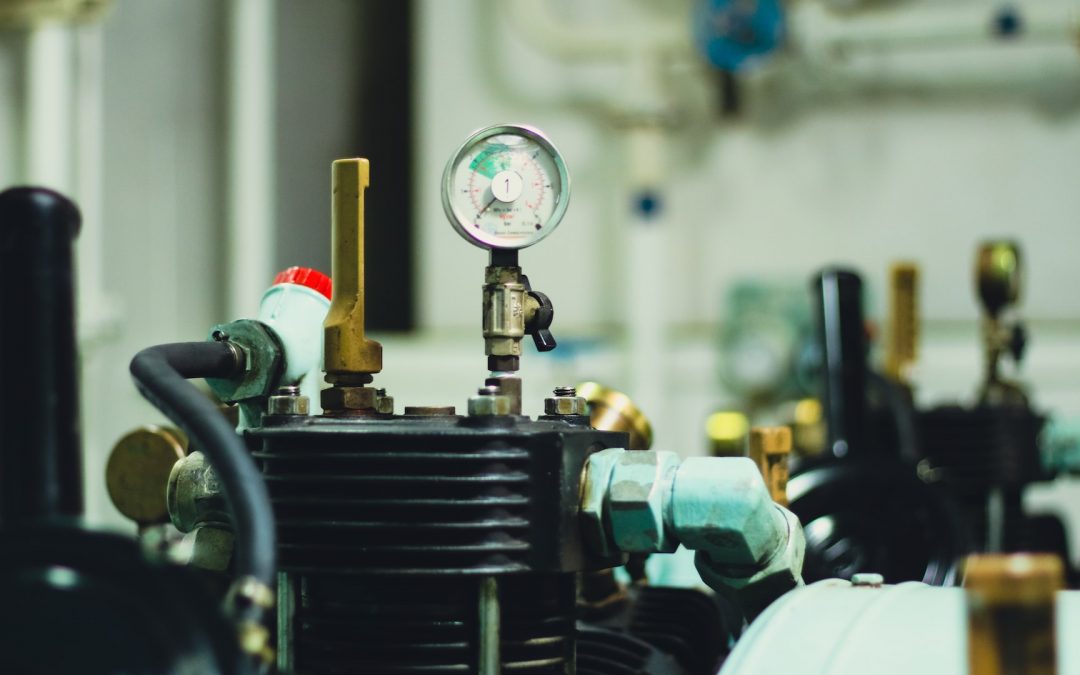

In order to keep that engine functioning properly, you have to remove the heat it produces and keep it cool. The best way to do that is with a coolant pump of some kind. While some coolant pumps use a synthetic coolant, many simply use water. One of these is called a hydronic cooling circulator pump, and it relies on a hydronic circulator pump motor.

Should I Replace the Pump or the Pump Motor?

Knowing which part of the cooling process is broken down can be tricky. However, more often than not, the motor is the culprit. Motors run themselves ragged far more often than pumps do. So, if you replace the hydronic circulator pump motor, you’re more than likely back in action. However, after a number of years, the pump itself may run out of steam, so to speak.

You can get your pump and motor evaluated by a professional, or take the leap and replace the motor each time the pump stops working. If you’re planning to continue using your machine long-term, it’s never a bad investment. If the problem turns out to be the pump itself, you’ll know when it doesn’t start back up again after replacing the motor. In this case, order yourself a new pump and save your new motor for the next break-down in function. Keeping a spare of each on-hand is also a great idea for anyone running a large system with regular need for replacement.

Replace Hydronic Circulator Pump Motor

If your trouble is with your hydronic circulator pump motor, L.N.Electric can help you replace it. Simply give us a call with the following information at the ready:

- Flow rate

- Head range

- Speed

- Catalogue number

- Model number

With this information, we can find you a replacement motor and send it right away.